The manufacturing industry has always relied on efficient and reliable heat treatment solutions to enhance the quality and durability of their products. One such solution that has gained popularity over the years is the walking beam furnace, offered by JiangSu YiNuo Thermal Energy Technology Co., Ltd.

What is a Walking Beam Furnace?

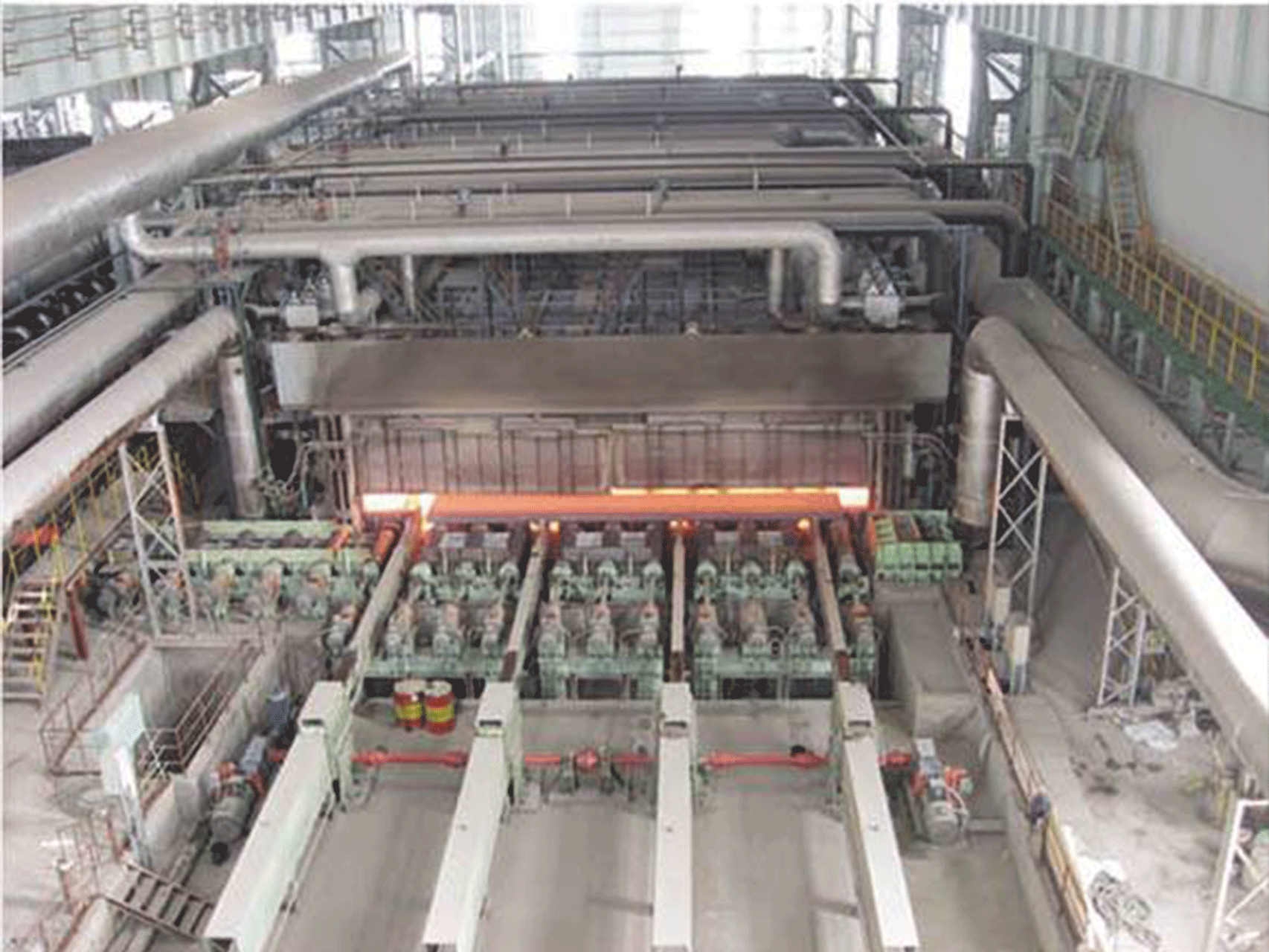

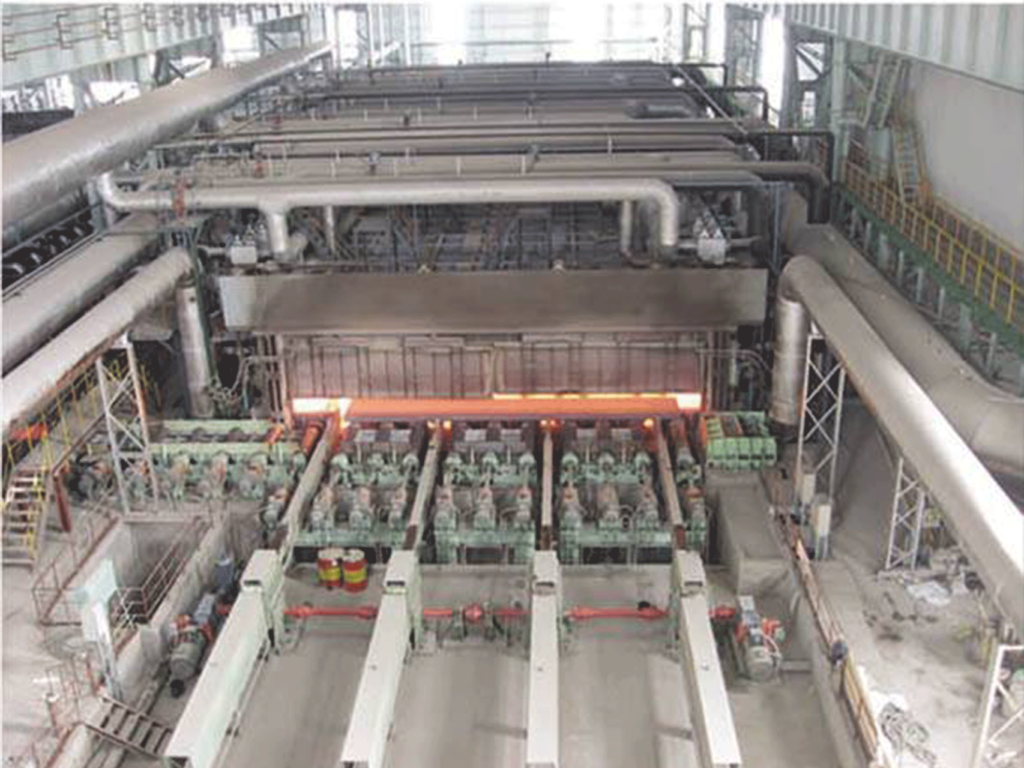

A walking beam furnace is an industrial furnace used for heat treatment processes such as forging, annealing, and hardening. The furnace features a conveyor system with beams that oscillate back and forth, allowing for the controlled movement of materials through the furnace. The beams move in a synchronized manner to maintain the stability of the load, ensuring even heating and cooling of the materials being processed.

The walking beam furnace is an ideal heat treatment solution for manufacturers who require efficient and reliable furnace systems to enhance their production processes. The target audience for this product includes manufacturers in the automotive, aerospace, and steel industries, among others. These manufacturers require heat treatment solutions that can handle high-volume and high-temperature materials while ensuring quality, reliability, and cost-effectiveness.

The walking beam furnace meets these needs by providing a stable and efficient conveyor system that can process a wide range of materials at high temperatures. It also ensures even heating and cooling of materials, minimizing the risk of defects and reducing production time.

Benefits of a Walking Beam Furnace

Walking beam furnaces offer numerous benefits that make them a popular choice for manufacturers across various industries. Some of the advantages of the furnace include:

1. Enhanced Product Quality: The walking beam furnace ensures that materials are heated and cooled uniformly, minimizing the risk of deformation and reducing the likelihood of defects in the final product.

2. Increased Efficiency: The furnace’s synchronized conveyor system ensures that materials are processed quickly and efficiently, reducing production time and costs.

3. Lower Energy Consumption: The walking beam furnace’s innovative design reduces energy consumption, making it an eco-friendly and cost-effective option for manufacturers.

Maximizing Efficiency with Walking Beam Furnaces: Tips and Tricks

Walking Beam Reheating Furnaces are a crucial component of the steel industry, as they play a vital role in the reheating process of steel products before they are rolled or forged. In today’s fast-paced steel industry, efficiency is critical, and maximizing the performance of the walking beam furnace is essential for maintaining high productivity levels. JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a leading manufacturer of walking beam furnaces, and they have developed some tips and tricks for maximizing the efficiency of these furnaces.

1. Optimize the Walking Beam Conveyor System

The walking beam conveyor system is the backbone of the walking beam furnace. It supports the steel products and moves them through the furnace, ensuring that they are heated evenly and consistently. To maximize the efficiency of the walking beam furnace, the conveyor system needs to be optimized. This can be achieved by ensuring that the conveyor speed is set correctly and that the walking beams are well-lubricated to reduce friction and wear. Additionally, the conveyor system’s design should be optimized to minimize heat loss and ensure that the steel products are heated as efficiently as possible.

2. Monitor Furnace Temperature

Monitoring the temperature inside the furnace is crucial for ensuring that the steel products are heated evenly and consistently. By monitoring the furnace temperature, operators can adjust the furnace’s settings to maintain the desired temperature range. This can help reduce energy waste and improve the furnace’s efficiency. Additionally, monitoring the furnace temperature can help operators identify any issues with the furnace’s heating system, allowing them to take corrective action before it affects the furnace’s performance.

3. Proper Maintenance and Cleaning

Regular maintenance and cleaning of the walking beam furnace are crucial for ensuring that it operates at peak efficiency. Proper maintenance includes checking and replacing any worn or damaged parts, cleaning the furnace’s interior, and ensuring that the conveyor system is well-lubricated. Regular maintenance and cleaning can help reduce downtime and extend the furnace’s lifespan, ultimately leading to lower operating costs and higher productivity levels.

How Do Walking Beam Furnaces Have Transformed Manufacturing Processes?

One of the leading manufacturers of walking beam furnaces is Jiangsu YiNuo Thermal Energy Technology Co., Ltd. The company has vast experience in designing, manufacturing, and installing walking beam furnaces for various industrial applications. Their furnaces are known for their high efficiency, low emissions, and reliable performance.

The working principle of walking beam furnaces is based on convection and radiation heating principles. The furnace utilizes a walking beam conveyor system that moves the steel products through a series of refractory-lined heating chambers. The chambers are heated using natural gas or other fuels, and the heat is transferred to the steel products through a combination of convection and radiation.

The walking beam conveyor system ensures that the steel products are moved through the furnace in a controlled and consistent manner, allowing them to be heated evenly and ensuring that they reach the desired temperature. This results in improved product quality and reduced energy consumption.

Walking Beam Furnaces vs. Pusher Furnaces: Which is Better for Your Industry?

Walking beam furnaces are designed to handle heavy loads and maintain precise temperature control throughout the heating process. They use a series of beams that move back and forth, carrying the load through the furnace while maintaining a consistent temperature. The walking beam furnace is commonly used in the steel industry for heating and forging steel products.

On the other hand, pusher furnaces use a conveyor system to push the load through the furnace. This furnace design is suitable for continuous production and can handle large volumes of materials. Pusher furnaces are often used in the heat treatment industry for annealing, normalizing, and stress-relieving processes.

So, which furnace is better for your industry? It depends on your specific needs and requirements. If you need to handle heavy loads and require precise temperature control, a walking beam furnace may be the better option. This is particularly true if you are in the steel industry, where temperature control is critical for producing high-quality steel products.

Conclusion

In conclusion, the walking beam furnace is an innovative and reliable heat treatment solution that meets the needs of various manufacturing industries. Its unique design offers numerous benefits, including enhanced product quality, increased efficiency, and lower energy consumption. The walking beam furnace’s target audience is manufacturers who require efficient, reliable, and cost-effective heat treatment solutions to enhance their production processes. JiangSu YiNuo Thermal Energy Technology Co., Ltd. provides this furnace and offers support and consultation to help manufacturers achieve their production goals.