Inquiry

walking beam furnace

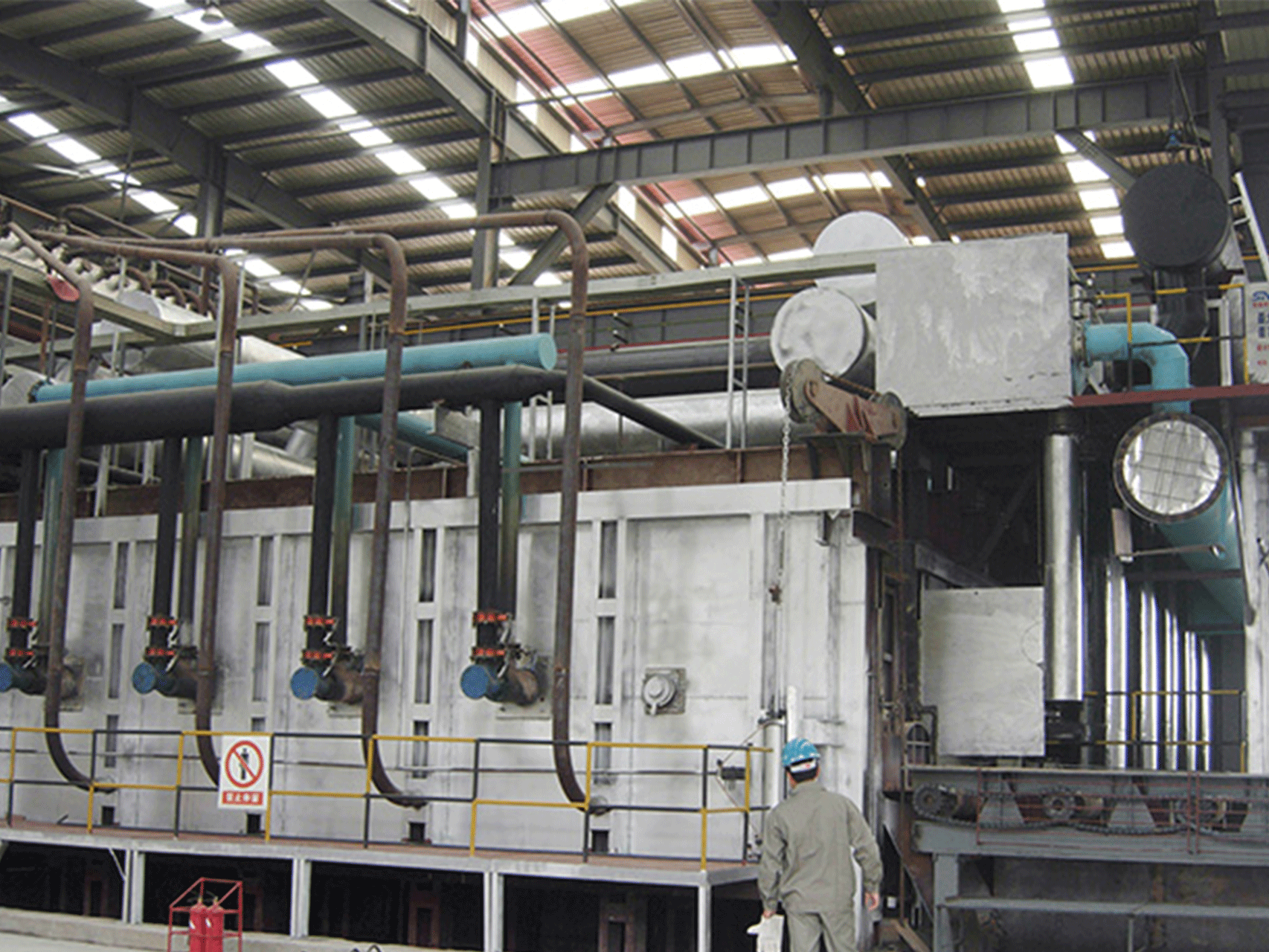

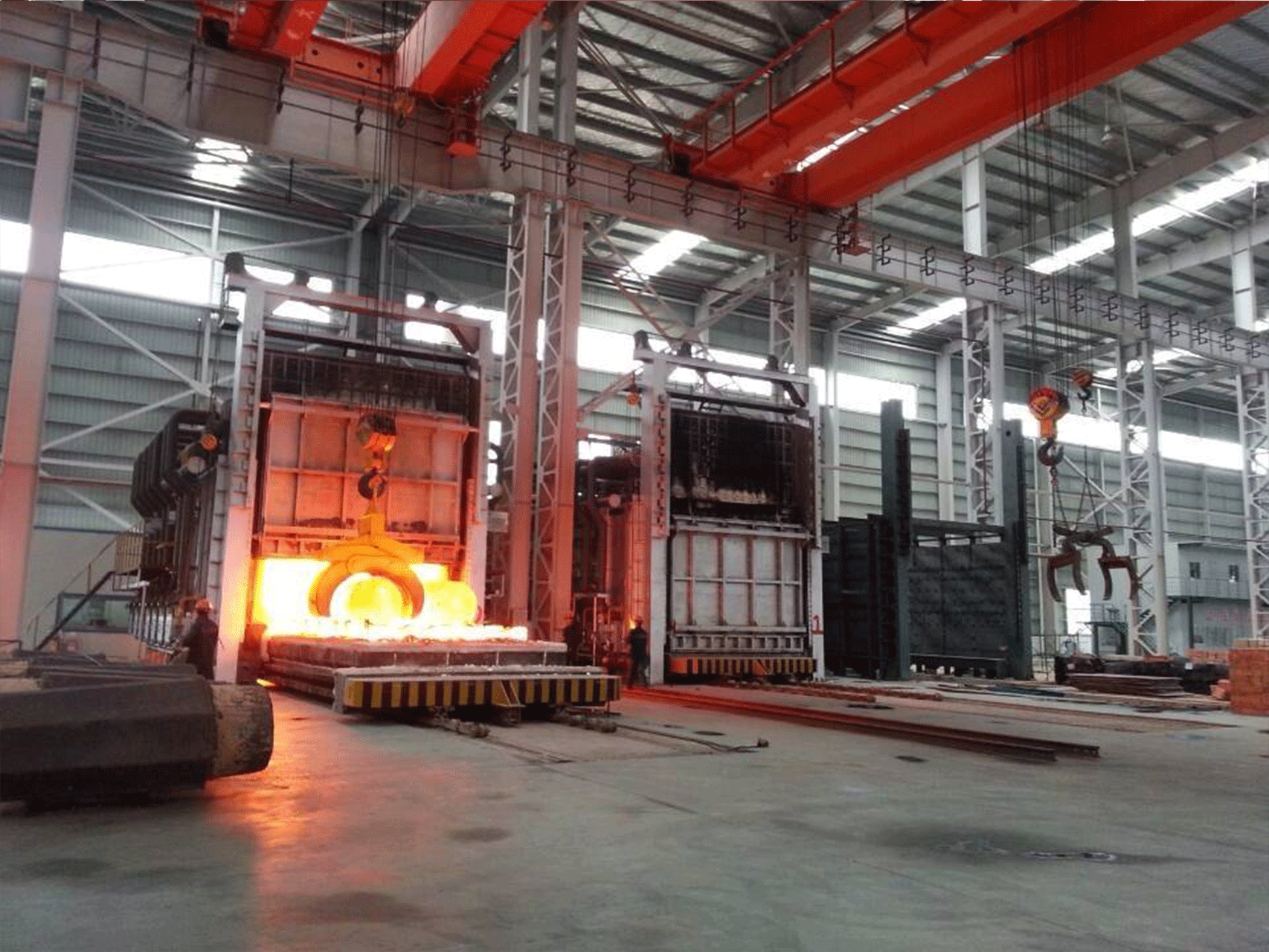

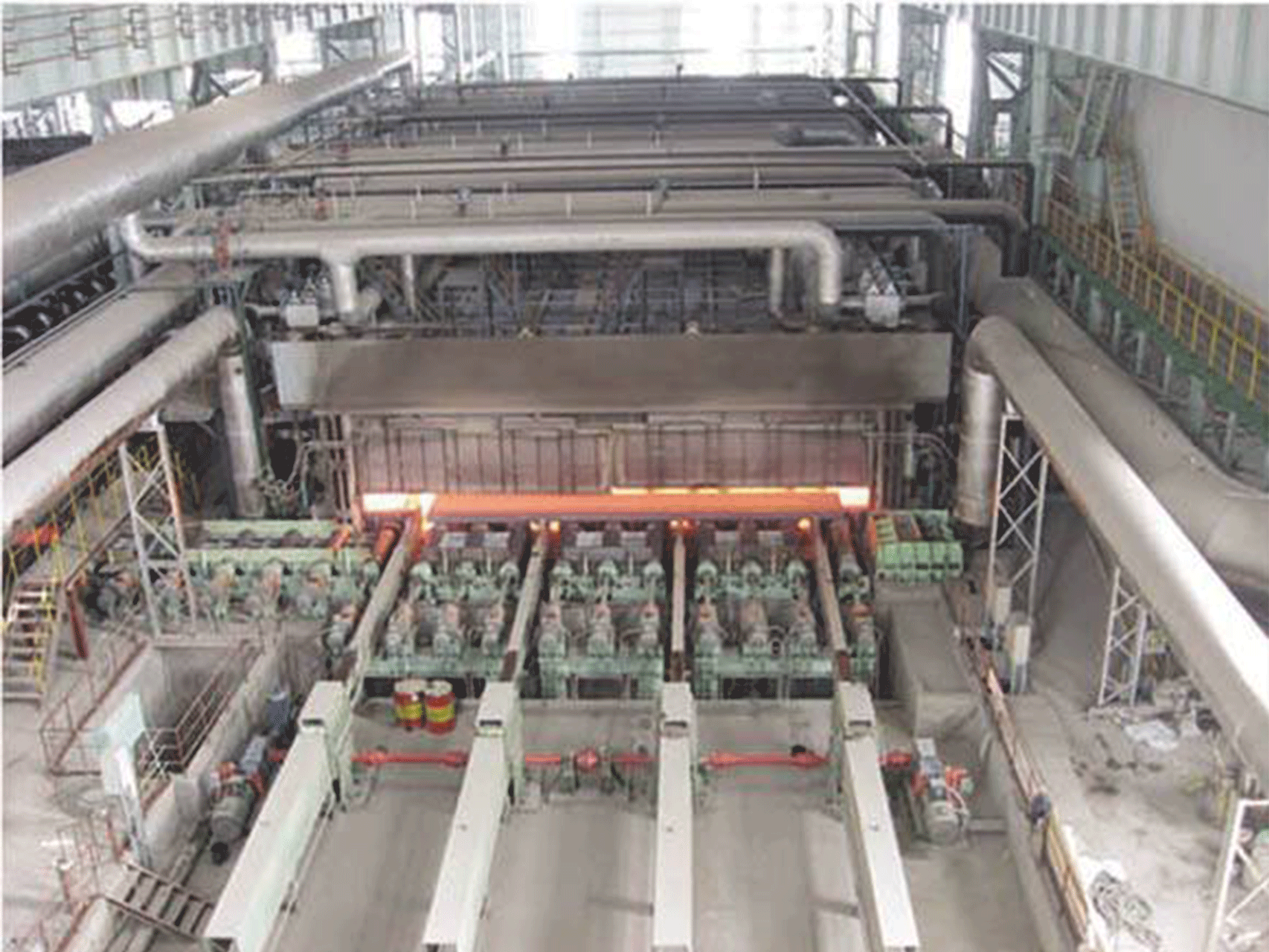

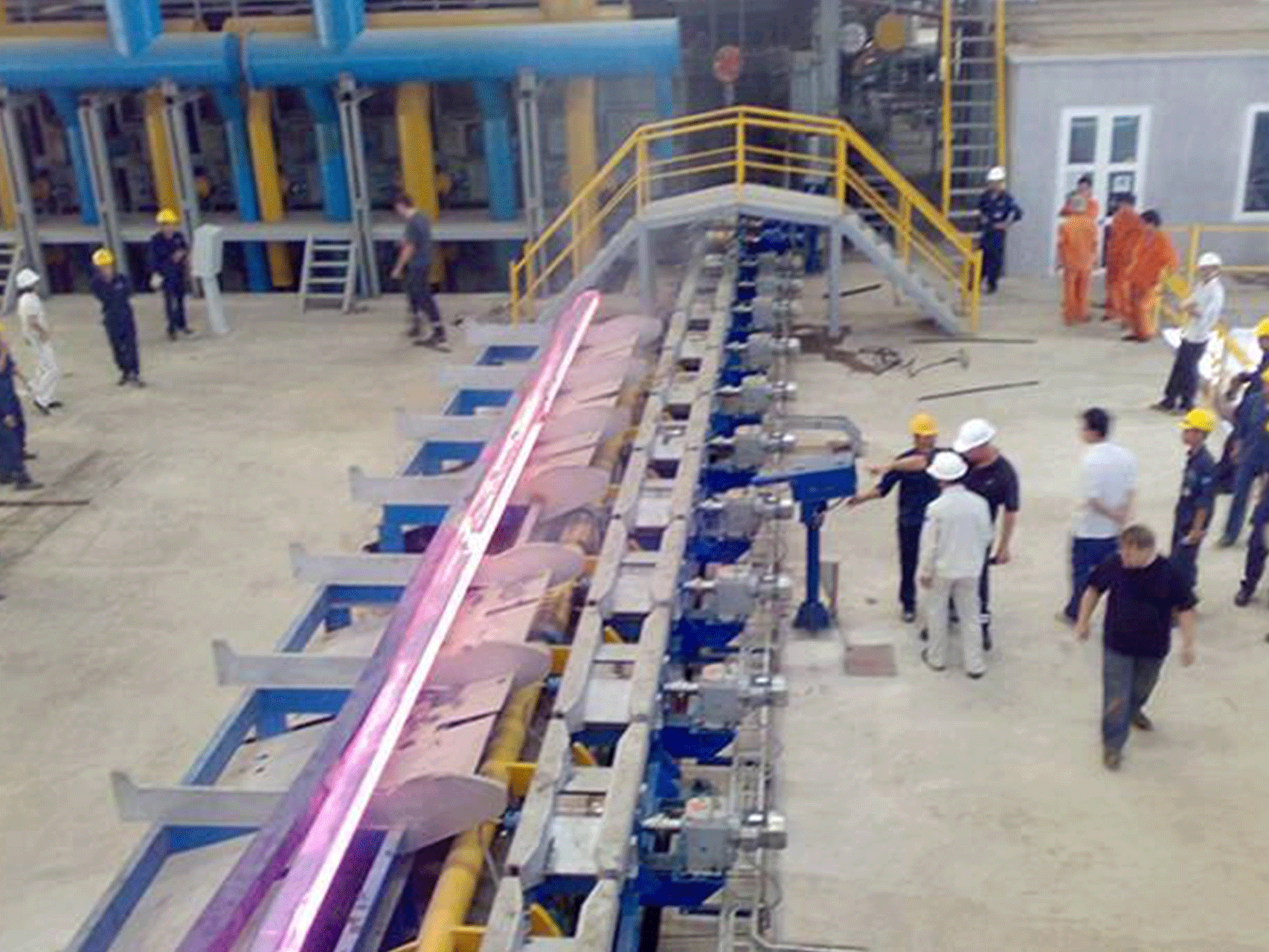

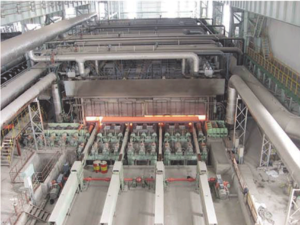

A walking beam furnace is a type of industrial furnace used for heating, reheating, and heat-treating materials such as steel, aluminum, and copper. A walking beam furnace gets its name from the fact that it transports materials through the furnace by moving a beam back and forth.

The furnace is made up of a chamber with heating elements and a conveyor system that moves materials through the chamber. The walking beam is a large horizontal beam with rollers or skids that support the materials as they are transported through the furnace. The beam moves back and forth in a reciprocating motion, with one end moving up and the other moving down.

Walking beam furnaces are widely used in the steel industry to heat and reheat steel products such as billets, blooms, and slabs prior to rolling or further processing. They can also be used to improve the strength and other mechanical properties of steel. Walking beam furnaces are popular for large-scale industrial applications due to their high efficiency and uniform heating.

Advantages of walking beam furnace

It has several advantages over other types of furnaces:

- High efficiency: It has a high thermal efficiency, which means it can heat materials quickly and with less fuel consumption.

- Uniform heating: It provides uniform heating to the materials being processed, which results in consistent quality and reduced material waste.

- Low maintenance: It has a simple design and requires minimal maintenance, which reduces downtime and maintenance costs.

- Versatility: It can be used for a variety of heating and heat treatment applications, making it a versatile tool in many industries.

- Automation: It can be fully automated, which reduces labor costs and improves efficiency.

- Safety: The walking beam furnace is designed with safety features to prevent accidents and injuries during the operation.

Overall, they offers high efficiency, uniform heating, low maintenance, versatility, automation, and safety, making it a popular choice in many industries.

Walking beam furnace FQA

Q: What types of materials can be processed in a walking beam furnace?

A: They can be used to process a wide variety of materials, including steel, aluminum, copper, and other metals, as well as glass and ceramics.

Q: How does a walking beam furnace work?

A: It uses a conveyor system to move materials through the furnace on a series of beams. The beams move in a cyclical motion, lifting the materials up and out of the furnace and then dropping them back down onto the next set of beams. The furnace heats the materials to the desired temperature using burners located above and below the beams. The materials are then cooled and removed from the furnace at the other end. The cycle repeats as new materials are fed into the furnace.

Q: What are the advantages of a walking beam furnace?

A: The advantages include high efficiency, precise temperature control, uniform heating, reduced maintenance, and increased throughput. The walking beam design allows for the continuous processing of materials, reducing idle time and increasing productivity. The furnace can also handle a wide variety of materials and can be customized to meet specific processing requirements.

Q: What are the key components of a walking beam furnace?

A: The key components of a walking beam furnace include:

- Conveyor system: This consists of a series of beams that move the materials through the furnace in a cyclical motion.

- Burners: These are located above and below the conveyor system and are used to heat the materials to the desired temperature.

- Temperature control system: This maintains precise temperature control within the furnace to ensure that the materials are heated uniformly.

- Exhaust system: This removes waste gases from the furnace to maintain a clean and safe working environment.

- Cooling system: This cools the materials as they exit the furnace to prevent damage or deformation.

- Control system: This oversees the operation of the furnace and ensures that all components are working together effectively.

Q: What are the applications of a walking beam furnace?

A: Applications include heat treating, forging, and annealing of various metals and alloys. They are commonly used in the steel, aluminum, and automotive industries, as well as in the production of aerospace components and industrial tools.

Q: What are the maintenance requirements for a walking beam furnace?

A: Maintenance requirements for a furnace include regular cleaning to remove debris and buildup, inspection and replacement of damaged or worn components, and lubrication of moving parts. Proper calibration of temperature and control systems is also essential to ensure consistent and accurate performance. Regular maintenance can help extend the life of the furnace and prevent downtime due to breakdowns or malfunctions.