Tunnel furnaces are an essential piece of equipment for various industries, including metalworking, ceramics, and glass production. They provide uniform heating and cooling of materials, making them crucial in the manufacturing process. JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a leading manufacturer of tunnel furnaces, and their products are used globally.

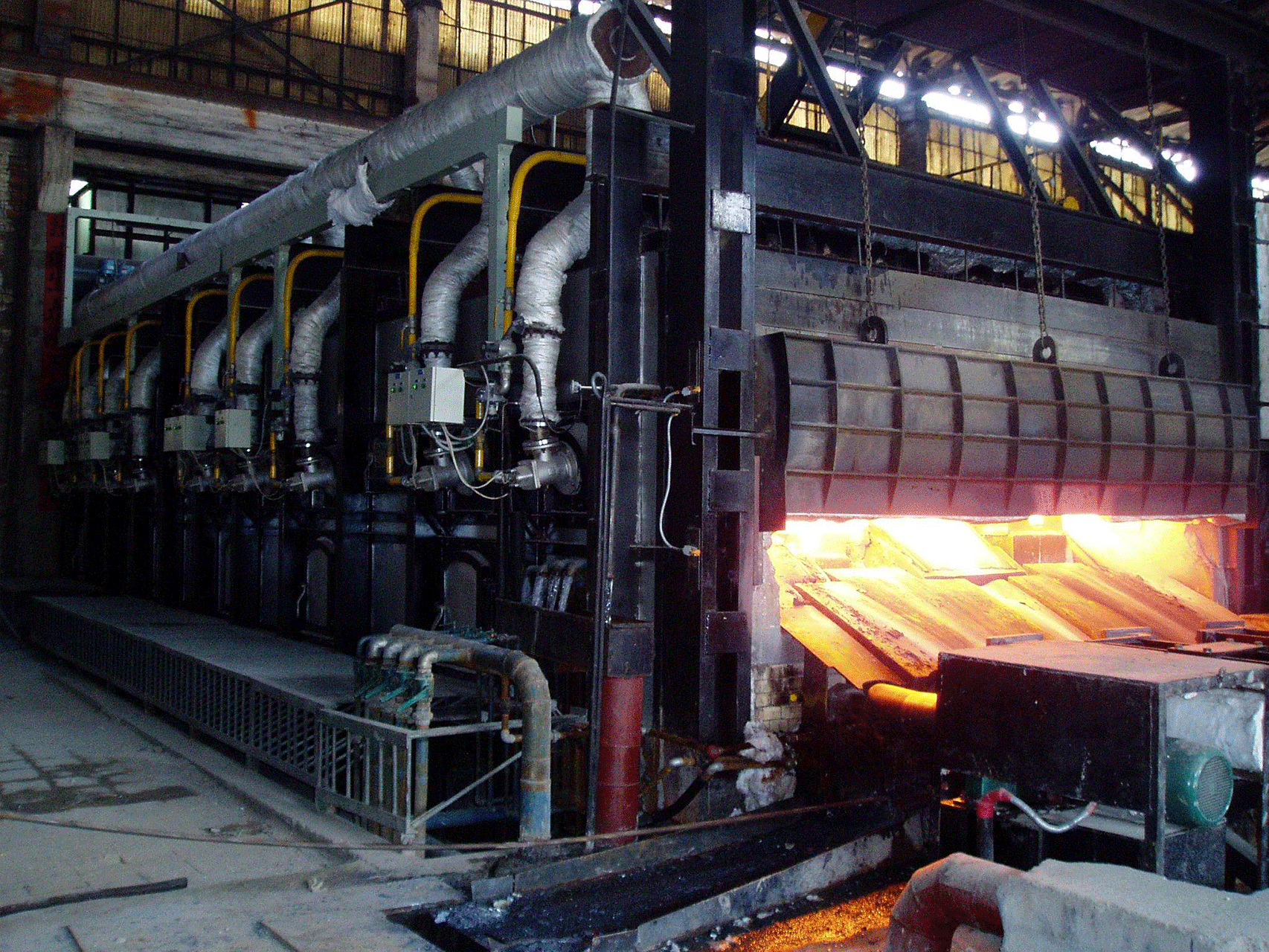

A tunnel furnace is a continuous heating and cooling system that passes a material through a tunnel while applying heat. The furnace’s design allows for the heating and cooling of materials in a controlled environment, ensuring consistent product quality. JiangSu YiNuo Thermal Energy Technology Co., Ltd. produces several types of tunnel furnaces, each tailored to meet specific industry needs.

FAQs about Tunnel Furnace

Tunnel furnaces are an essential component of many manufacturing processes. They are used for the heating, annealing, and sintering of a wide range of materials, including ceramics, glass, metals, and plastics. Tunnel furnaces offer many advantages, including precise temperature control, uniform heating, and energy efficiency. However, for those who are new to the world of industrial furnaces, there may be some questions about tunnel furnaces.

1. What is a tunnel furnace?

A tunnel furnace is a type of industrial furnace that is used for the continuous heating, annealing, and sintering of materials. The furnace is designed as a long, narrow tunnel with a conveyor system that carries the materials through the furnace.

2. What are the components of a tunnel furnace?

The main components of a tunnel furnace include the furnace chamber, the heating system, the conveyor system, and the control system. The furnace chamber is made of refractory materials to withstand high temperatures. The heating system can be electric, gas-fired, or oil-fired. The conveyor system is used to transport the materials through the furnace at a controlled speed. The control system is used to monitor and control the temperature, speed, and other parameters of the furnace.

3. What are the advantages of using a tunnel furnace?

Tunnel furnaces offer several advantages, including:

Precise temperature control: The temperature inside the furnace can be controlled with a high degree of accuracy, ensuring consistent and repeatable results.

Uniform heating: The materials are heated evenly as they pass through the furnace, reducing the risk of thermal shock and other defects.

Energy efficiency: The design of the furnace minimizes heat loss, resulting in lower energy consumption and lower operating costs.

Continuous operation: Tunnel furnaces are designed for continuous operation, which can improve efficiency and reduce labor costs.

4. What materials can be processed in a tunnel furnace?

Tunnel furnaces can be used to process a wide range of materials, including ceramics, glass, metals, and plastics. The specific type of furnace and heating system will depend on the material being processed and the desired result.

5. How is the temperature controlled in a tunnel furnace?

The temperature in a tunnel furnace is controlled using a temperature controller, which monitors the temperature inside the furnace and adjusts the heating system accordingly. The temperature can be controlled to within a few degrees Celsius, depending on the accuracy of the temperature controller.

6. How is the speed of the conveyor system controlled?

The speed of the conveyor system is controlled using a variable frequency drive (VFD), which adjusts the speed of the motor that drives the conveyor. The speed can be adjusted to control the residence time of the materials inside the furnace, which can affect the final product quality.

Features of JiangSu YiNuo Thermal Energy Technology Co., Ltd.’s Tunnel Furnace

One of the key features of JiangSu YiNuo Thermal Energy Technology Co., Ltd.’s tunnel furnaces is their energy efficiency. They are designed to use less energy than traditional furnaces, resulting in reduced operating costs. Additionally, the company’s furnaces are equipped with advanced control systems that allow for precise temperature and atmosphere control, further improving energy efficiency.

Another significant advantage of JiangSu YiNuo Thermal Energy Technology Co., Ltd.’s tunnel furnaces is their flexibility. They can handle various materials and product shapes, including long and flat items. Furthermore, their furnaces can operate at high temperatures, up to 1600°C, allowing for the production of materials that require extreme heat.

JiangSu YiNuo Thermal Energy Technology Co., Ltd.’s tunnel furnaces are also designed to be reliable and easy to maintain. They use high-quality components and are built to withstand harsh environments, ensuring long-term performance. The company provides excellent after-sales support, including technical assistance and spare parts, to ensure their customers’ continued satisfaction.

Tunnel Furnace vs. Rolling Mill Heating Furnace: Which is Better for Your Needs

When it comes to heating metal for industrial purposes, two common options are the tunnel furnace and the rolling mill heating furnace. While both types of furnaces serve the same basic purpose, they each have unique features and advantages that make them better suited for different needs.

So, which type of furnace is better for your needs? It depends on the specific requirements of your operation. If you need to heat large quantities of metal continuously and precisely control the temperature throughout the process, a tunnel furnace may be the better choice. On the other hand, if you are primarily focused on heating metal for use in a rolling mill and need a furnace that can quickly heat the metal to a specific temperature, a rolling mill heating furnace may be the better option.

The cost of installation and maintenance is an essential factor to consider when choosing between the two furnaces. However, the type of metal being heated is also crucial in determining the best option. Certain metals require precise temperature control and slower heating processes to avoid warping or cracking, while others can be heated quickly without such concerns.

Ultimately, the decision between a tunnel furnace and a rolling mill heating furnace will depend on the specific needs of your operation. JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a manufacturer of both types of furnaces and can provide guidance on selecting the best option for your needs based on factors like your budget, the type of metal being heated, and the specific heating process required.

Conclusion

JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a reputable manufacturer of tunnel furnaces, providing reliable and energy-efficient equipment for various industries. Their tunnel furnaces are flexible, can operate at high temperatures, and are easy to maintain, making them a popular choice for companies worldwide. With their commitment to quality and after-sales support, JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a trusted partner for businesses seeking to enhance their manufacturing processes.