A single stage coal gasifier is a type of gasifier used to convert solid coal into a combustible gas. Gasification is a process that involves breaking down coal into its component gases using high temperatures and a limited amount of oxygen. The resulting gas can be used as a fuel for various applications such as heating, electricity generation, and industrial processes.

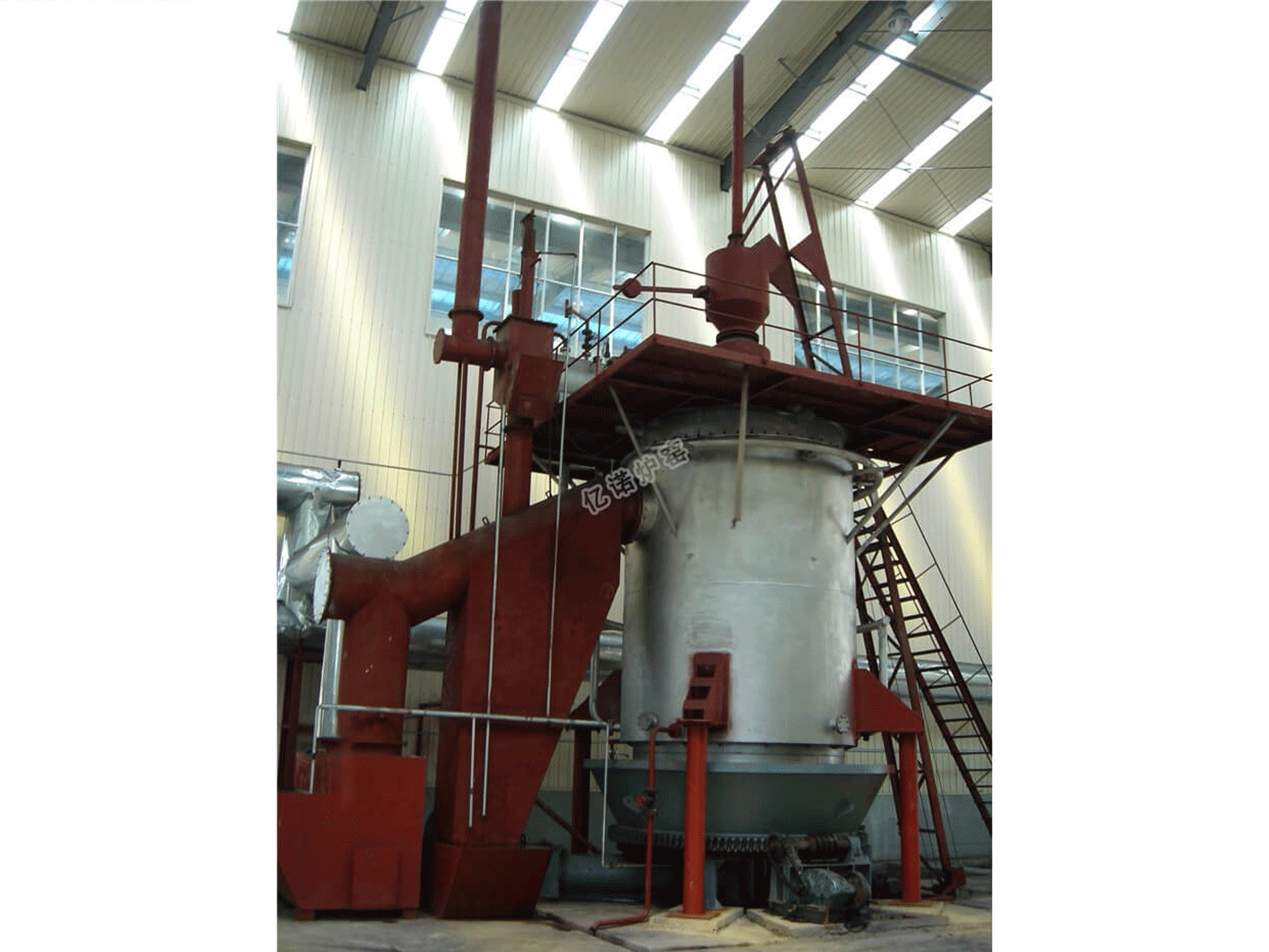

In a single stage coal gasifier, the gasification process takes place in a single reactor vessel. The coal is introduced into the reactor along with a limited amount of air or oxygen. The temperature in the reactor is typically between 800-1000°C (1472-1832°F), which causes the coal to undergo a series of chemical reactions that convert it into gas. The gas produced by the gasifier contains mainly carbon monoxide, hydrogen, methane, and other hydrocarbons.

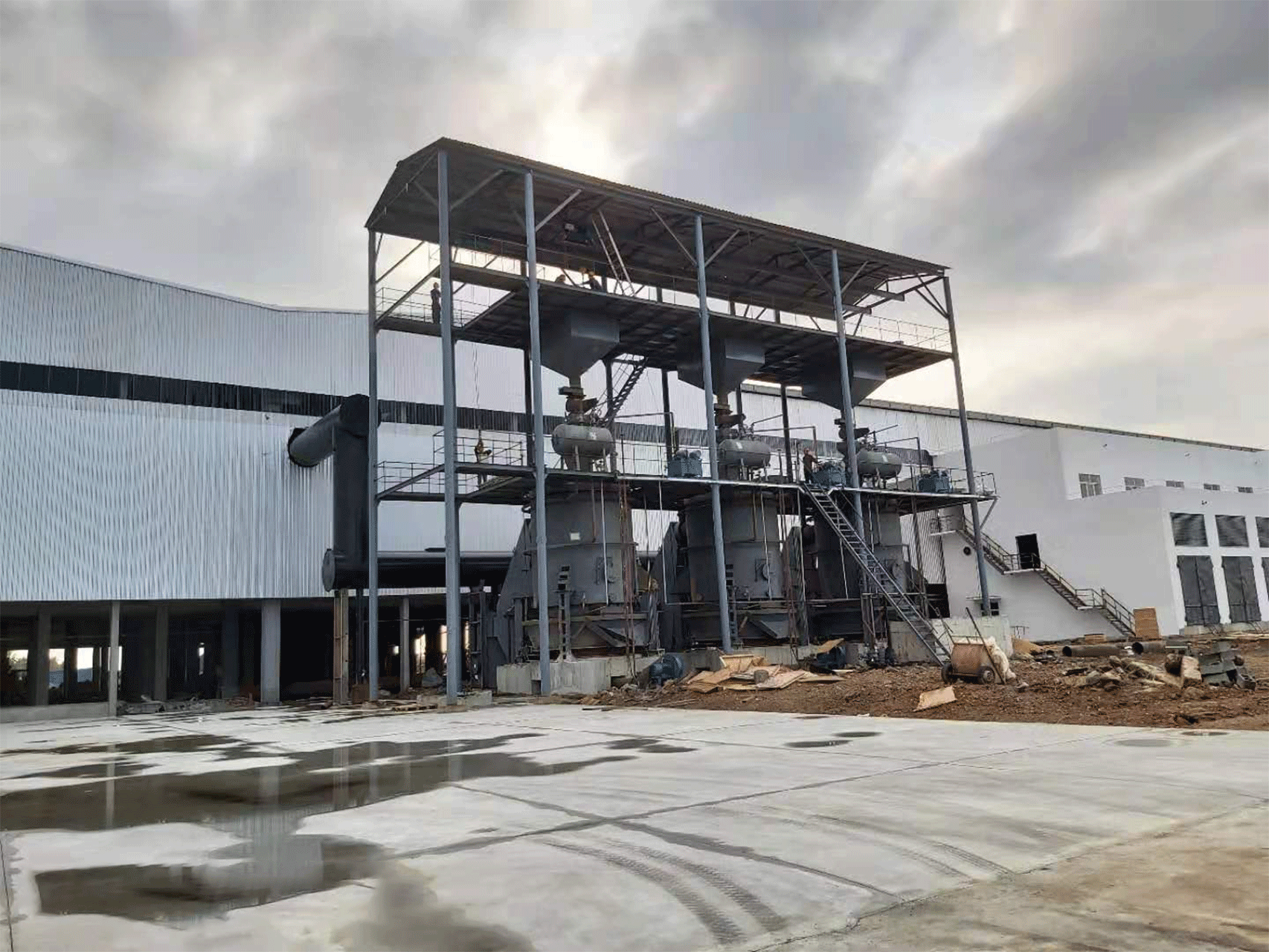

The advantage of a single stage coal gasifier is that it is relatively simple and can be operated with a minimal amount of equipment. It also has a small footprint, making it suitable for use in small-scale industrial applications. However, the gas produced by a single stage coal gasifier has a relatively low calorific value and may contain impurities such as sulfur, which can be harmful to the environment.

Overall, single stage coal gasification technology has been used for many decades and continues to play an important role in the energy industry, particularly in countries where coal is abundant and alternative energy sources are limited.

Single Stage Coal Gasifier: working principle

The working principle of a single stage coal gasifier involves the conversion of solid coal into a gaseous fuel through a process called gasification. Gasification is a high-temperature process that converts carbon-based materials such as coal into a mixture of gases known as syngas.

The gasification process takes place in a single reactor vessel, where coal is introduced along with a limited amount of air or oxygen. The reactor is heated to temperatures ranging from 800-1000°C (1472-1832°F) to create a reducing atmosphere, which helps to break down the coal into its component gases.

As the coal is heated, it undergoes a series of chemical reactions that produce a mixture of gases including carbon monoxide, hydrogen, methane, and other hydrocarbons. The syngas produced by the gasifier can be used as a fuel for various applications, including power generation and industrial processes.

The gasification process in a single stage coal gasifier typically involves four main steps: drying, devolatilization, gasification, and combustion. During the drying stage, the moisture content of the coal is removed through the application of heat. In the devolatilization stage, the volatile components of the coal are released as gases. The gasification stage involves the conversion of the remaining solid carbon into gases, and the combustion stage involves the burning of the gases to release heat.

Overall, the working principle of a single stage coal gasifier involves the controlled conversion of solid coal into a combustible gas through a series of high-temperature chemical reactions. The resulting syngas can be used as a fuel for various applications, providing an alternative to traditional fossil fuels.

The characteristics

The characteristics of a single stage coal gasifier include:

- High-temperature operation: Single stage coal gasifiers operate at high temperatures of 800-1000°C (1472-1832°F) to facilitate the gasification process.

- Limited oxygen supply: A limited amount of oxygen or air is supplied to the gasifier to create a reducing atmosphere that helps break down the coal into gases.

- Single-stage operation: The gasification process takes place in a single reactor vessel, which simplifies the gasification process and reduces the need for additional equipment.

- Produces syngas: The gasifier produces a mixture of gases known as syngas, which consists primarily of carbon monoxide, hydrogen, methane, and other hydrocarbons.

- Low ash content: Compared to other coal conversion technologies, single stage coal gasifiers produce syngas with low levels of ash and other impurities.

| Single-stage gas generator technical performance parameters | |||||||

| Model | YDSQ1.0 | YDSQ1.5 | YDSQ2.0 | YDSQ2.4 | YDSQ2.6 | YDSQ3.0 | YDSQ3.2 |

| Type | CG1Q1.0-1 | CG1Q1.5-1 | CG1Q2.0-1 | CG1Q2.4-1 | CG1Q2.6-1 | CG1Q3.0-1 | CG1Q3.2-1 |

| Inner diameter of furnace chamber(mm) | 1000 | 1500 | 2000 | 2400 | 2600 | 3000 | 3200 |

| Cross-sectional area of furnace chamber(m²) | 0.785 | 1.77 | 3.14 | 4.52 | 5.31 | 7.07 | 8.04 |

| Height of fuel layer(mm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Height of fire layer(mm) | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 |

| Height of ash layer(mm) | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 |

| Heating area of water jacket(m²) | 6.84 | 10.09 | 20.06 | 27.16 | 31.51 | 32.4 | 31.35 |

| Applicable coal type | Unbonded or weakly bonded anthracite, bituminous coal or coking coal Coal quality should meet the requirements of GB-9143 | ||||||

| Coal size(mm) | 13-25 | 13-25、25-50 | |||||

| Coal consumption(kg/h) | 125-198 | 280-440 | 500-792 | 720-1144 | 850-1320 | 1130-1782 | 1280-2035 |

| Gasification agent | Air + water vapor | ||||||

| Air consumption(m³/kg coal) | 2.2-2.8 | 2.2-2.8 | 2.2-2.8 | 2.2-2.8 | 2.2-2.8 | 2.2-2.8 | 2.2-2.8 |

| Steam consumption(kg/kg coal) | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 |

| Gas production(Nm²/h) | 450-715 | 980-1540 | 1750-2750 | 2500-3960 | 3000-4730 | 3950-6237 | 4480-7117 |

| Gas calorific value(kj/m³) | 5020-6060 | 5020-6060 | 5020-6060 | 5020-6060 | 5020-6060 | 5020-6060 | 5020-6060 |

| Gas outlet pressure(pa) | <950 | <980 | <980 | <980 | <1500 | <1500 | <1500 |

| Gas outlet temperature(℃) | 400-550 | 400-550 | 400-550 | 400-550 | 400-550 | 400-550 | 400-550 |

| Max. furnace bottom blast pressure(pa) | 2000 | 2450 | 3500 | 3500 | 4000 | 6000 | 6000 |

| Saturated air temperature(℃) | 50-65 | 50-65 | 50-65 | 50-65 | 50-65 | 50-65 | 50-65 |

| Probe hole steam seal pressure(kpa) | <294 | <294 | <294 | <294 | <294 | <294 | <294 |

| Water jacket steam output(kg/h) | 150-200 | 250-300 | 300-350 | 450-500 | 450-500 | 500-600 | 500-650 |

| Water jacket steam pressure(kpa) | <294 | <294 | <294 | <294 | <294 | <294 | <294 |

| Coal addition method | Bellows coal addition, mechanical coal addition | ||||||

| Maximum speed of ash tray(rh) | 2.87 | 2.76 | 2.23 | 2 | 1.7 | 1.7 | 1.7 |

| Power of ash tray drive motor(kw) | 3 | 3 | 4 | 4 | 4 | 5.5 | 5.5 |

| Power of coal bucket lifting motor(kw) | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 3 | 3 |

| Slag discharge form | Wet type, automatic slag discharge | ||||||