Gas Fired Furnaces offer a cost-effective and reliable source of heat for many industrial processes, making them an essential part of many manufacturing and production facilities. However, with technology advancing rapidly, it may be time for industries to consider upgrading their gas-fired furnaces to newer, more efficient models.

Upgrading to a newer model of a gas-fired furnace can offer several benefits to industries. First and foremost, newer models are designed to be more energy-efficient, meaning they use less gas to produce the same amount of heat. This results in lower energy costs for industries, which can have a significant impact on their bottom line.

Additionally, newer gas furnaces come with advanced features such as programmable thermostats, variable speed blowers, and electronic ignition systems that make them easier to operate and more convenient to use.

What Is a Gas Fired Furnace?

A gas-fired furnace is a heating system that burns natural gas or propane to generate heat. The heat produced by the furnace is then distributed throughout a building or home via a network of ducts and vents.

Gas-fired furnaces come in different types and sizes, ranging from small residential units to large industrial furnaces. They can be designed for a variety of applications, including central heating systems, space heating, and process heating.

The furnace consists of several key components, including a burner, heat exchanger, blower, and control system. The burner is responsible for igniting the gas and creating a flame, while the heat exchanger transfers the heat from the flame to the air that circulates through the system. The blower then distributes the warm air throughout the building or home, and the control system regulates the temperature and operation of the furnace.

How Does Gas Fired Furnace Work?

A gas-fired furnace is a common heating system that works by burning natural gas or propane to generate heat, which is then distributed throughout a building or home via a network of ducts and vents. However, there are different types of gas-fired furnaces, each with its unique features and applications. One such type is the regenerative gas-fired forging furnace, which is commonly used in industrial applications.

A regenerative gas-fired forging furnace works by using burners to heat the air and fuel mixture in the combustion chamber. The hot gases produced by the combustion process are then passed through a ceramic heat exchanger, which absorbs the heat and transfers it to the incoming air and fuel mixture. This preheating of the air and fuel mixture allows for more efficient combustion and reduces fuel consumption.

The heat exchanger in a regenerative furnace is designed with two chambers, one for heating and one for cooling. The hot gases flow through the heating chamber, and the cooled gases flow through the cooling chamber, which is filled with a material such as ceramic bricks or honeycomb structures that can absorb and store heat.

After a set period, the flow of hot gases is reversed, and the cool gases are redirected to the heating chamber, while the hot gases are directed to the cooling chamber. This process allows the heat exchanger to be continuously regenerated, and the furnace can maintain a constant temperature without requiring excessive amounts of fuel.

In addition to the heat exchanger, a regenerative furnace may also have a combustion control system that monitors the temperature and oxygen levels in the combustion chamber and adjusts the fuel and air mixture to maintain optimal combustion efficiency. This system can also help reduce emissions, making the furnace more eco-friendly.

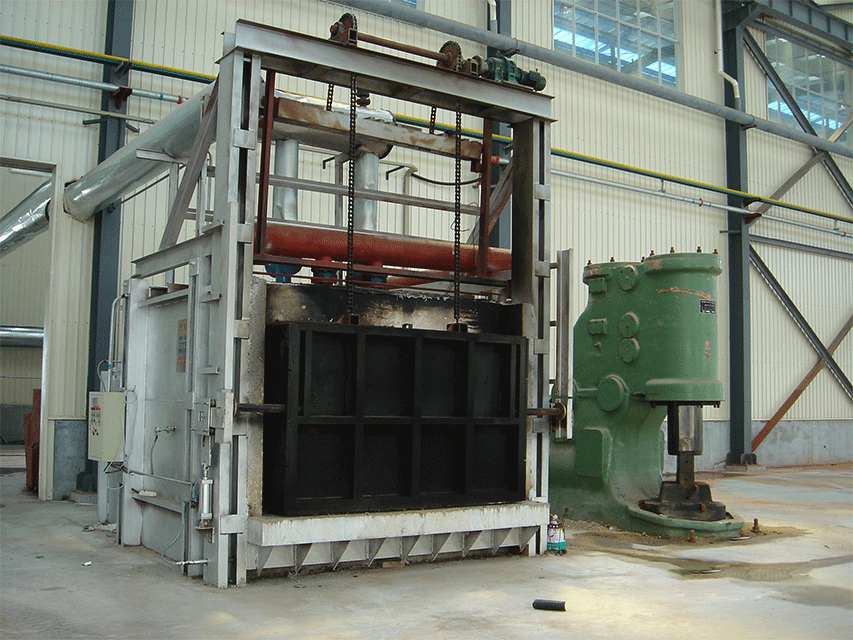

Regenerative Gas Fired Forging Furnace for Sale

Regenerative gas-fired forging furnaces are popular heating solutions in many industrial applications. These furnaces are highly efficient, eco-friendly, and designed to withstand the rigors of heavy-duty industrial applications. In this blog, we will discuss the key features of a regenerative gas-fired forging furnace.

1) Feature of Regenerative Gas-Fired Forging Furnace

Regenerative heat recovery system: The primary feature of a regenerative gas-fired forging furnace is its regenerative heat recovery system. This system recovers waste heat from the furnace and uses it to preheat the incoming combustion air, which increases the efficiency of the furnace. This system allows for significant energy savings and can result in lower fuel costs for manufacturers.

2) High-temperature capabilities:

Another key feature of these furnaces is their ability to reach very high temperatures, making them suitable for use in forging processes that require high temperatures. These furnaces can typically reach temperatures between 1,200°C and 1,500°C, which is necessary for the forging and heat-treating metals.

3) Consistent temperature control:

Regenerative gas-fired forging furnaces are designed to maintain a consistent temperature, which is important for producing high-quality forged products. These furnaces come with advanced temperature control systems that ensure that the furnace operates at a stable temperature and prevents temperature fluctuations that can affect the quality of the finished products.

Why Regenerative Gas-Fired Forging Furnaces are the Top Choice for Industry Heating?

JiangSu YiNuo Thermal Energy Technology Co., Ltd. has become the top choice for industry heating due to several factors that set them apart from other manufacturers of regenerative gas-fired forging furnaces.

Firstly, they have a strong focus on research and development, with a team of experts that continuously improve and innovate their furnaces to meet the changing needs of the industry. This commitment to research and development has enabled them to produce furnaces that are highly efficient, eco-friendly, and reliable.

Secondly, their furnaces are made using high-quality materials and components, ensuring that they can withstand the high temperatures and stresses associated with industrial forging processes. This makes them a reliable and cost-effective heating solution for manufacturers, with minimal downtime or maintenance needed.

Thirdly, they offer a range of customizations and configurations to meet the specific needs of different industrial applications. They work closely with their clients to understand their unique heating requirements and provide customized solutions that are tailored to their needs.

Lastly, their furnaces come with advanced control systems that ensure optimal temperature control and energy efficiency, reducing fuel consumption and leading to cost savings for manufacturers in the long run.

Bottom Line

JiangSu YiNuo Thermal Energy Technology Co., Ltd. stands out as the top choice for industry heating due to its commitment to research and development, use of high-quality materials, customization options, and advanced control systems. With their expertise and focus on innovation, they are well-positioned to continue leading the industry in the production of high-quality, reliable, and efficient regenerative gas-fired forging furnaces.