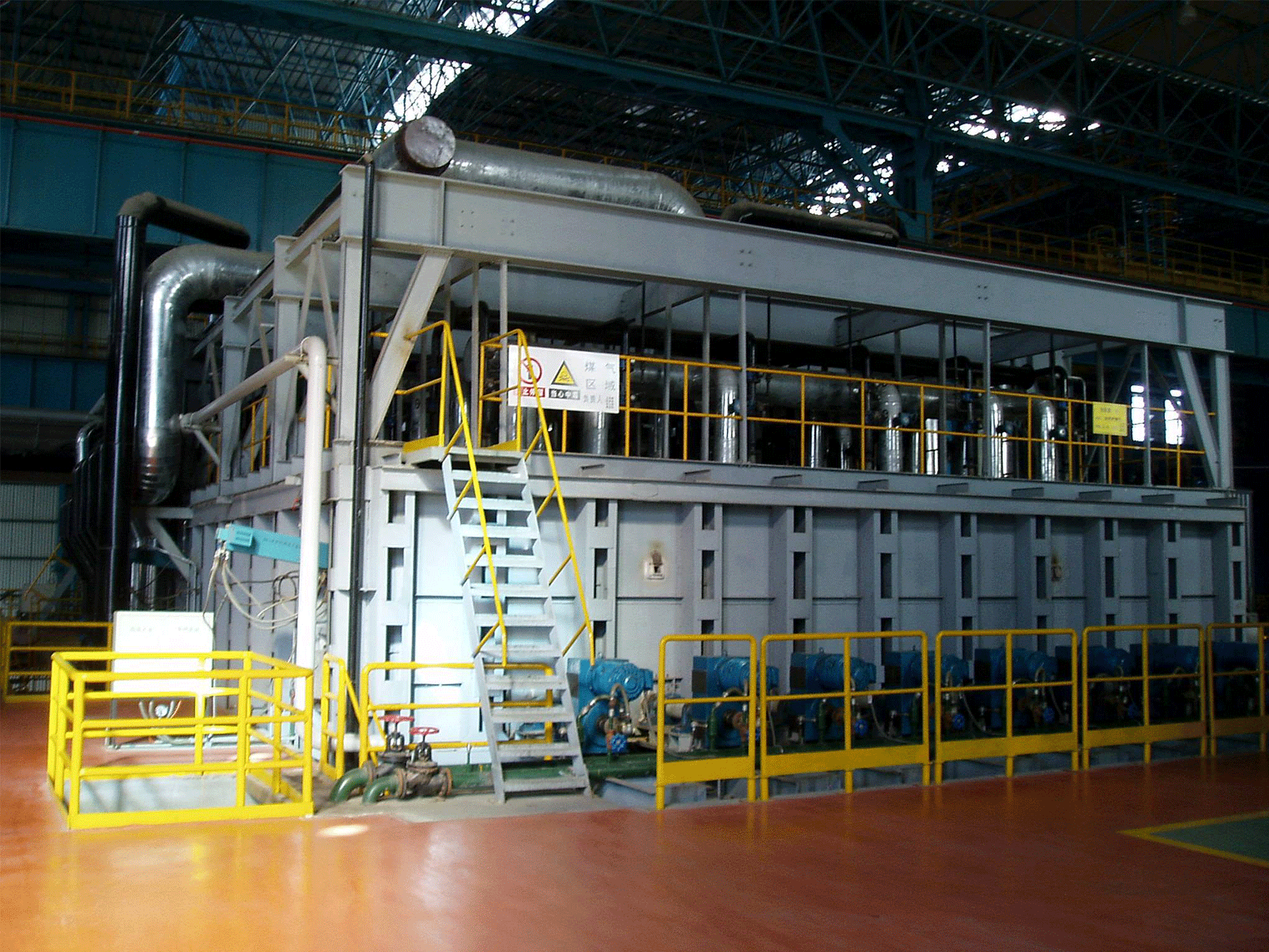

A Reheating Furnace for Steel Rolling is a specialized industrial furnace used to heat steel billets, blooms, or slabs to the precise temperature required for further shaping through rolling or forging. The furnace ensures that the steel reaches a plastic state, allowing it to be deformed without cracking or structural failure.

These furnaces are essential in the steel and metalworking industries and are commonly used to prepare raw steel for products such as automotive parts, construction materials, and various metal components.

Heating Process and Operation

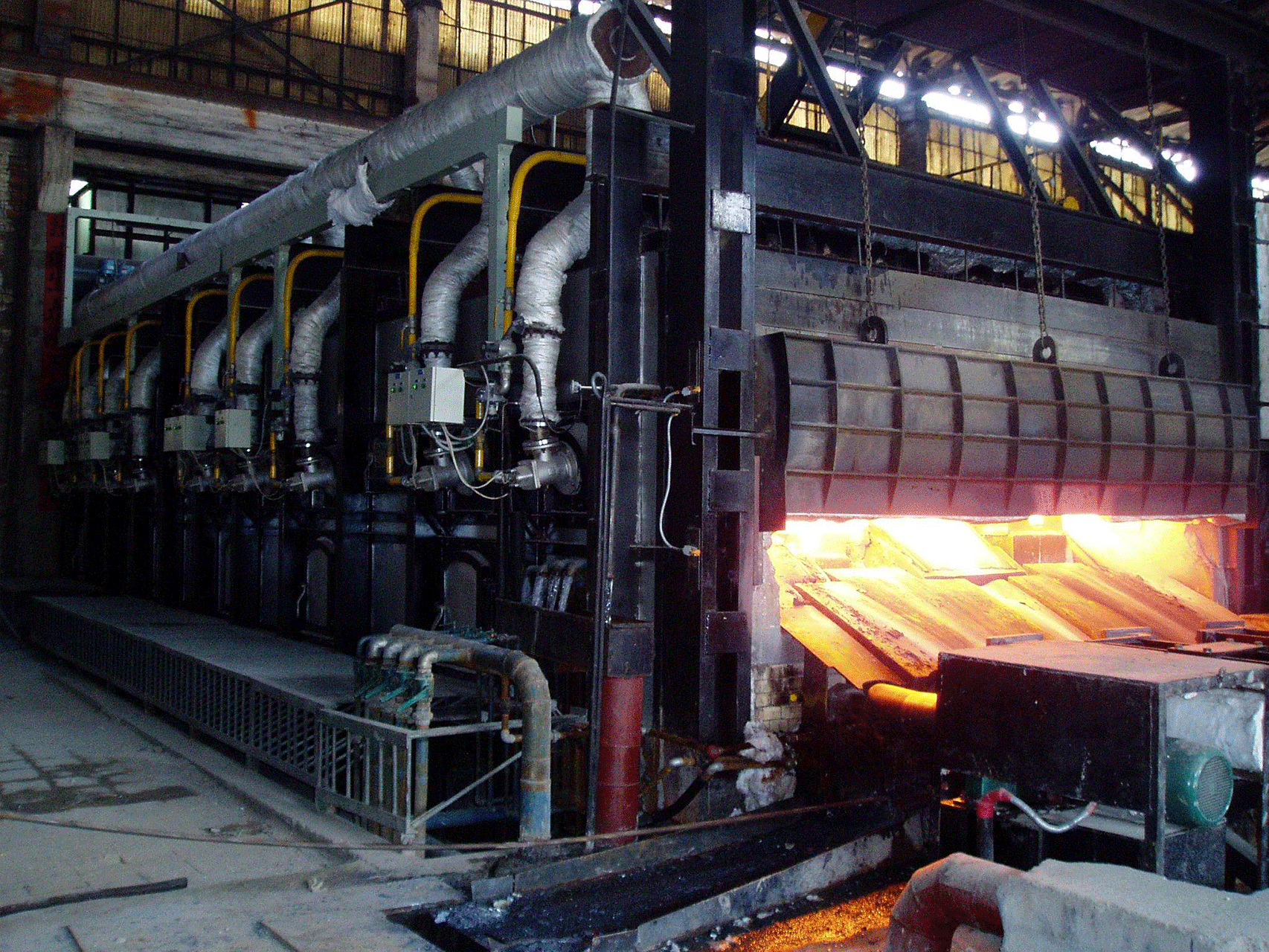

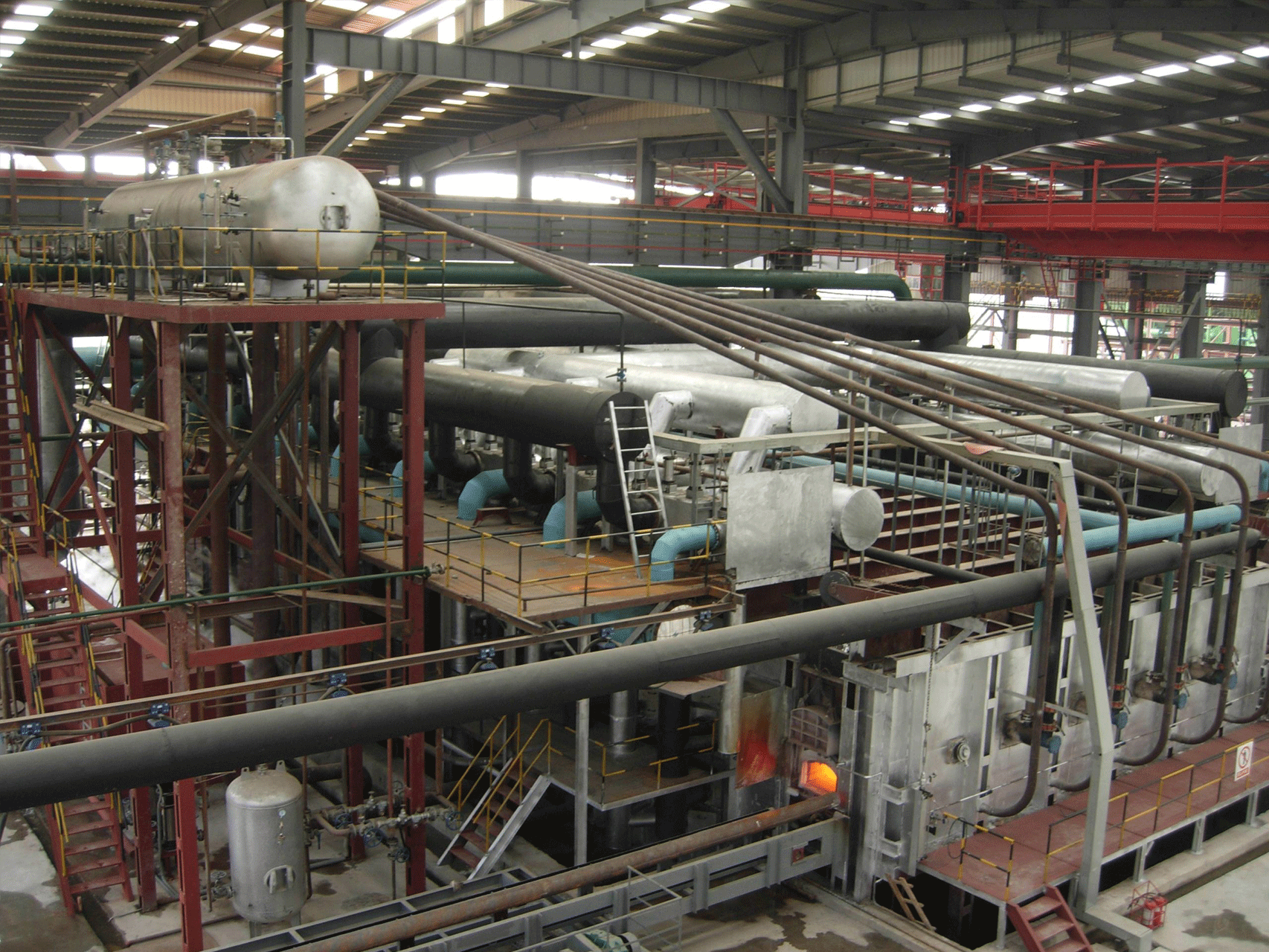

The heating process in a Reheating Furnace for Steel Rolling typically uses natural gas or electricity as a fuel source. Steel materials are loaded onto a conveyor system, such as a walking beam or pusher-type mechanism, which moves them through the furnace chamber.

Inside the chamber, the steel is heated using burners or electric heating elements, and the temperature is precisely controlled through advanced temperature sensors and automation systems. These controls ensure that each piece of steel is heated evenly and reaches the specific temperature range needed for optimal rolling or forging.

Once the steel reaches the desired temperature—often between 1,100°C and 1,250°C, depending on the steel grade and process—it is discharged from the furnace and sent directly to the rolling mill or forging equipment.

Working Principle of Reheating Furnace for Steel Rolling

The working principle of a Reheating Furnace for Steel Rolling is based on controlled high-temperature heating of steel to prepare it for plastic deformation. Here’s how it functions:

1. Fuel Combustion or Electrical Heating

Heat is generated via natural gas burners or electric elements, depending on the furnace type. This heat is transferred to the steel through radiation and convection inside a refractory-lined chamber.

2. Conveyor System

The furnace uses an integrated mechanical handling system (e.g., walking beam or roller hearth) to move steel continuously through the furnace zones, ensuring consistent heating exposure.

3. Temperature Control

Advanced sensors and control units monitor the temperature of both the furnace atmosphere and the steel itself, adjusting burner output or element power as needed to maintain target heat profiles.

4. Discharge and Processing

Once the target temperature is achieved, the steel exits the furnace and is passed to rolling mills (for forming into sheets, rods, or bars) or to forging presses and hammers for shaping.

Key Features and Benefits

-

High Energy Efficiency: Designed to minimize heat loss and maximize thermal transfer, often incorporating regenerative or recuperative burner systems.

-

Precise Thermal Control: Real-time monitoring and automated adjustment ensure product quality and metallurgical consistency.

-

Uniform Heating: Conveyor systems and multiple heating zones allow for even distribution of heat across all steel surfaces.

-

Process Safety: Equipped with alarms, shut-off valves, flame detection, and emergency control systems to ensure safe and continuous operation.

-

Adaptability: Suitable for various steel grades and product types, including billets, blooms, and slabs of different dimensions.

Applications

Reheating Furnaces for Steel Rolling are commonly used in:

- Steel manufacturing plants

- Hot rolling mills

- Forging and extrusion facilities

- Automotive component production

- Heavy machinery and infrastructure fabrication

Characteristics of Reheating Furnace for Steel Rolling

A Reheating Furnace for Steel Rolling is engineered to meet the demanding requirements of industrial steel processing. It combines efficiency, precision, safety, and adaptability to deliver consistent performance across a wide range of applications. Below are some of its defining characteristics:

🔹 High Heating Efficiency

Reheating Furnaces for Steel Rolling are designed for optimal thermal performance. Equipped with efficient burners or electric heating systems and optimized insulation, these furnaces apply heat uniformly across steel surfaces. This not only reduces heat loss but also minimizes energy consumption and operating costs, making them ideal for high-throughput production environments.

🔹 Precise Temperature Control

Advanced temperature sensors and control systems allow for accurate monitoring and regulation of heat throughout the furnace chamber. This ensures that the steel is consistently heated to the correct temperature range required for rolling, which is critical for maintaining material integrity and achieving the desired mechanical properties.

🔹 Robust Safety Features

Safety is a top priority in the operation of any Reheating Furnace for Steel Rolling. These systems are equipped with:

- Temperature and pressure sensors

- Emergency shut-off switches

- Over-temperature alarms

- Automated control interlocks

These features help detect and respond to anomalies, preventing equipment damage and ensuring safe operation.

🔹 Versatility and Fuel Flexibility

Reheating Furnaces are versatile and capable of processing various steel products such as billets, rods, sheets, and slabs. They can also be adapted to run on multiple fuel types—including natural gas, electricity, or propane—based on facility requirements and fuel availability. This flexibility makes them suitable for a wide range of industrial setups.

Reheating Furnace for Steel Rolling is a high-performance, reliable, and safe solution for preparing steel for deformation. Its energy efficiency, precise control, and adaptability make it a cornerstone of modern steel manufacturing and processing lines.